Drying Step in RAD140 Production: A Critical Process to Ensure Product Stability and Quality

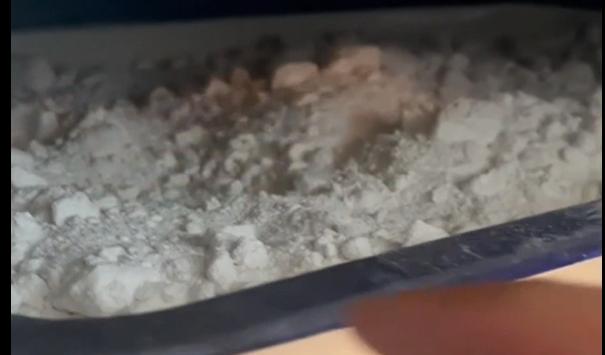

In the synthesis of RAD140, the preceding reaction and purification steps have already completed the chemical structure formation and purification. However, at this stage, the product remains in a moist intermediate state. The RAD140 product still contains a certain amount of solvent, which must be removed in the subsequent drying process. Through drying, the solvent gradually evaporates, ultimately transforming RAD140 into a dry powder form.

Drying is not merely a process of removing solvent—it also plays a crucial role in ensuring the stability and storability of RAD140. If the moist intermediate is not properly dried, residual solvents may remain, which can affect the final product’s purity, quality, and bioactivity. Residual solvents can also lead to degradation or unwanted reactions during storage, thereby compromising long-term stability and safety. Therefore, the drying step is essential for ensuring the final quality of RAD140.

Detailed Steps of the Drying Process

Placing the Product into Drying Equipment

After undergoing crystallization purification and other steps, the RAD140 product still contains a significant amount of solvent and remains moist. At this stage, the product is placed into specialized drying equipment. Inside the dryer, with the aid of temperature control systems and airflow, the solvent is evaporated through heat and ventilation.

Controlling Drying Temperature and Time

The drying process must be carried out under strictly controlled temperature conditions. Excessively high temperatures can lead to degradation or side reactions of RAD140, affecting the final product quality. Conversely, if the temperature is too low, the solvent may not fully evaporate, leaving residual solvent behind. Therefore, the temperature must be precisely regulated—typically set within an optimal range—to ensure RAD140 is effectively dried without damage.

Additionally, drying time must be carefully managed. This process usually takes about 24 hours. This duration is sufficient to ensure complete solvent evaporation while avoiding any potential adverse effects from prolonged heat exposure. Over-drying may cause physical or chemical changes to the product, while under-drying could result in incomplete solvent removal. Thus, balancing time and temperature is crucial.

Impact of Drying on RAD140 Purity and Stability

During the drying process, solvent removal helps enhance the stability of RAD140 and ensures its bioactivity. Residual solvents can negatively affect RAD140's purity and efficacy, particularly for components sensitive to solvents. Therefore, thorough drying is a necessary step to ensure the product remains unaffected during storage and use.

Furthermore, as a biologically active compound, RAD140’s stability directly influences its performance. In application, residual solvents can destabilize RAD140 molecules, reducing their effectiveness. The successful execution of the drying step thus ensures the performance and safety of RAD140 in its intended use.