Crystallization Purification in RAD140 Production: Ensuring High Purity of the Final Product

Crystallization purification is a critical step in the production of RAD140. Through this process, impurities in the intermediates can be removed, ensuring that the final product meets purity standards. Crystallization purification not only directly impacts the quality of RAD140, but also plays a crucial role in its effectiveness during application. In the following sections, we will explore in detail the crystallization purification steps in RAD140 production and understand its role and significance in the synthesis process.

The Relationship Between Intermediate Synthesis and Crystallization Purification in RAD140

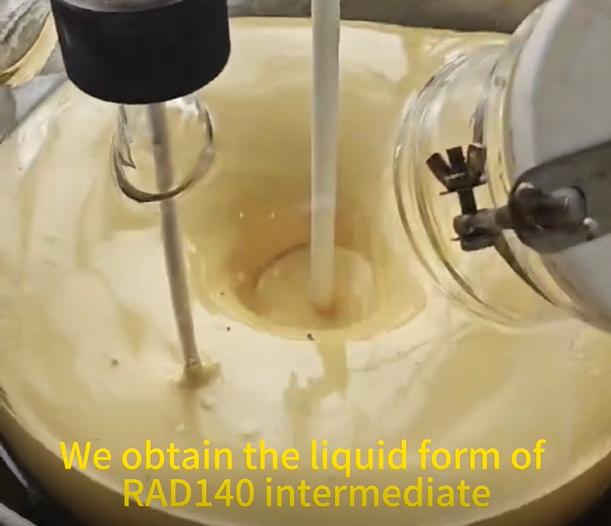

The synthesis of RAD140 involves multiple chemical reaction steps, each requiring precise control of reaction conditions to ensure the purity and quality of the intermediates. During the initial high-temperature reactor stage, the intermediate of RAD140 is successfully obtained. Although the intermediate has undergone reactions, it may still contain some impurities. To achieve a highly pure RAD140 final product, crystallization purification is necessary.

Crystallization purification is an effective separation and purification technique. By controlling solvent selection, temperature, and cooling rate, the main component in the intermediate can crystallize out from the solution, thereby removing impurities. In RAD140 production, crystallization purification not only increases the purity of the intermediate but also provides cleaner raw materials for subsequent drying and final product production.

The Principle of Crystallization Purification

The basic principle of crystallization purification relies on differences in solubility. By selecting an appropriate solvent and dissolution temperature, the target compound can crystallize out during the cooling process while impurities remain in the solution. As the temperature gradually decreases, solubility drops and the solute begins to form solid crystals. Compared to impurities, the crystallization of the target compound tends to be more stable and purer.

In the crystallization purification of RAD140, selecting a suitable solvent is one of the key factors. The chosen solvent must effectively dissolve the intermediate of RAD140 and facilitate its crystallization during cooling, without introducing additional impurities. Therefore, laboratories will select the appropriate solvent based on the properties of the RAD140 intermediate and will strictly control the crystallization temperature and cooling rate.

The Impact of Crystallization Purification on Final Purity

The quality of crystallization purification directly affects the purity of the final RAD140 product. If the solvent is not properly chosen or if the temperature is not precisely controlled during this process, impurities may remain, negatively impacting the final purity of RAD140. High-purity RAD140 is essential for its bioactivity, stability, and effectiveness in applications. For instance, higher purity RAD140 can bind more efficiently to androgen receptors, maximizing its effectiveness while minimizing side effects.

https://youtube.com/shorts/yfvCmQyelDY

Conclusion

Crystallization purification is one of the key steps in the production of RAD140. It ensures the purity of intermediates and directly affects the quality of the final product. Scientific solvent selection, precise temperature control, and appropriate cooling rates are all critical factors in achieving high-purity RAD140 intermediates. As technology continues to develop and improve, crystallization purification techniques will further advance, providing higher quality assurance for RAD140 production and meeting the market and consumer demands for high-purity products.