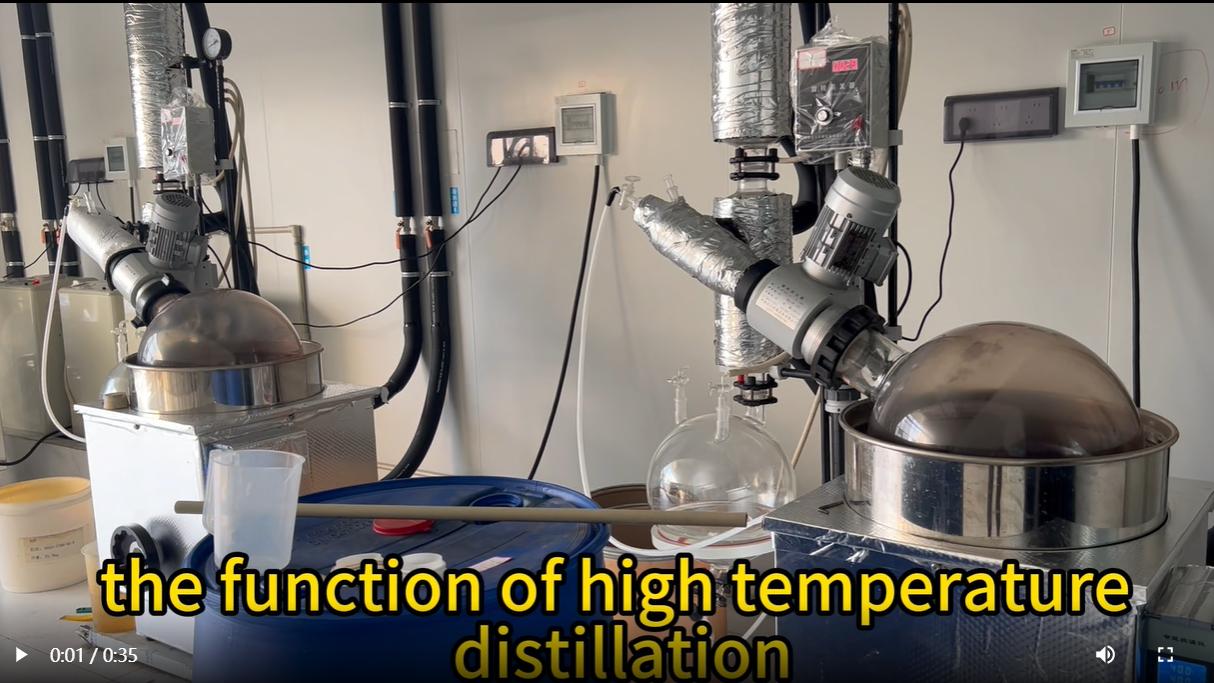

High-temperature distillation In GPCRMS lab

In chemical experiments and the production of pharmaceutical intermediates, high-temperature distillation is a common and crucial operation. It not only affects the efficiency of purification but directly impacts the final product quality and experimental safety. Today, let's take MK2866 as an example to discuss the importance of high-temperature distillation in actual production and the precautions that must be taken during the process.

We've previously explained the basic principle of high-temperature distillation: by heating the mixture, components with different boiling points are separated, achieving purification. The high-temperature distillation process we are observing today involves MK2866, a compound widely used in scientific research and biotechnology.

During the distillation process, our technicians must keep a close eye on the reaction at all times. If the heating is too intense or improperly controlled, the solution may boil violently, potentially leading to splashing, container breakage, or other dangerous situations. This not only causes waste of raw materials but also poses a threat to the safety of the operators. Therefore, careful monitoring of the temperature, the operation of the condenser, and any changes in the reaction liquid's state are crucial.

In the production of products like MK2866, MK677, and RAD140, every step requires precise execution. For example, the temperature must be set strictly within the boiling point range of the compound, the sealing of glassware must ensure stable pressure, and the cleanliness of the entire setup directly affects the purity of the final product. In addition to MK2866, other compounds such as MK677 and RAD140 also require high-temperature distillation during their production, and the process for these is quite similar. However, it places even higher demands on the technicians' experience and attention to detail.

High-temperature distillation is not just a technical task but a job that demands a great deal of responsibility. During the prolonged operation, technicians must maintain intense focus, constantly adjusting the heating power, observing the liquid level, recording data, and responding quickly to any anomalies. A single small mistake can lead to the failure of an entire batch or even trigger a safety incident.

Because of this, we insist on a meticulous, detailed, and professional work attitude in every high-temperature distillation operation. Whether it's the stability of the product or the high standards of quality demanded by clients, it all depends on the dedication and responsibility of our technicians at the front lines.

In conclusion, high-temperature distillation is not just a purification method; it is a precise technical operation that requires a combination of experience, focus, and a strong sense of responsibility. In the production of products like MK2866, MK677, and RAD140, the careful work of each technician is the foundation of ensuring product quality and customer satisfaction. Every drop of distillate in the laboratory is a commitment to quality and safety.