How to deal with unfinished production and experiments

In scientific research and chemical production processes, there’s a very practical issue that often goes unnoticed by outsiders—how to properly handle unfinished experiments or intermediate products at the end of each workday. This is especially true for liquids used in reactions or those being processed; if they are not carefully stored before completion, they can become contaminated, degrade, or even compromise the entire experiment. So, how do we safely and effectively manage these incomplete production or experimental liquids? Let's take the MK2866 distillation liquid we encountered today as an example to explain our standard procedures and precautions.

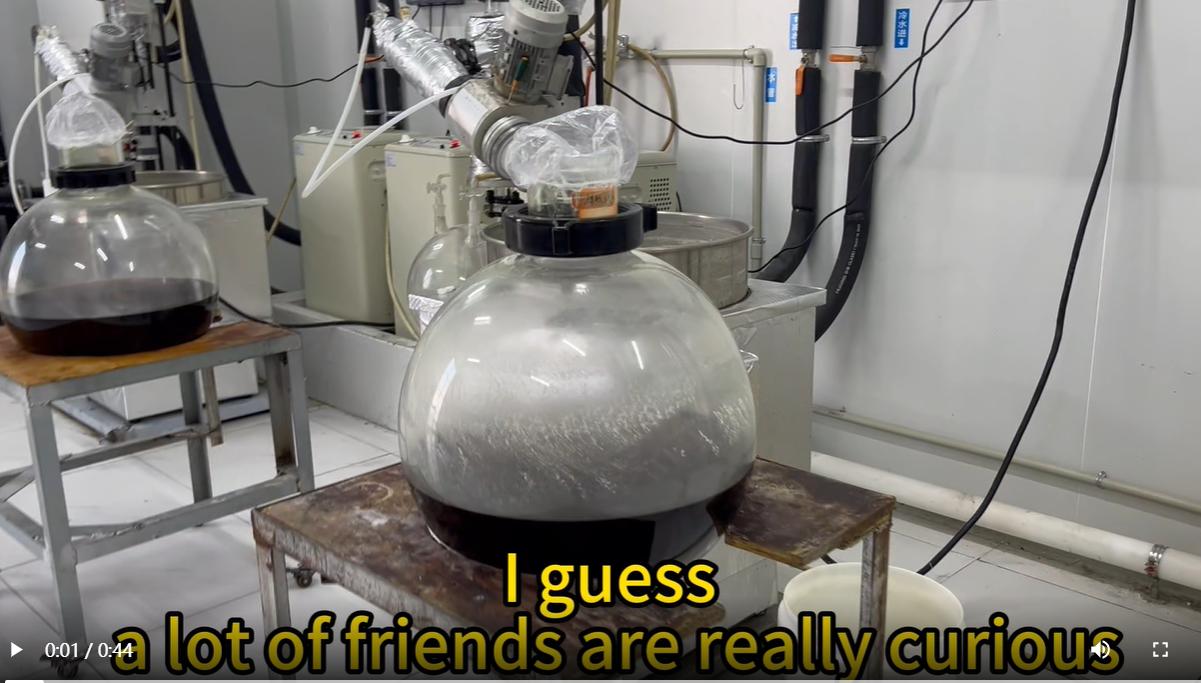

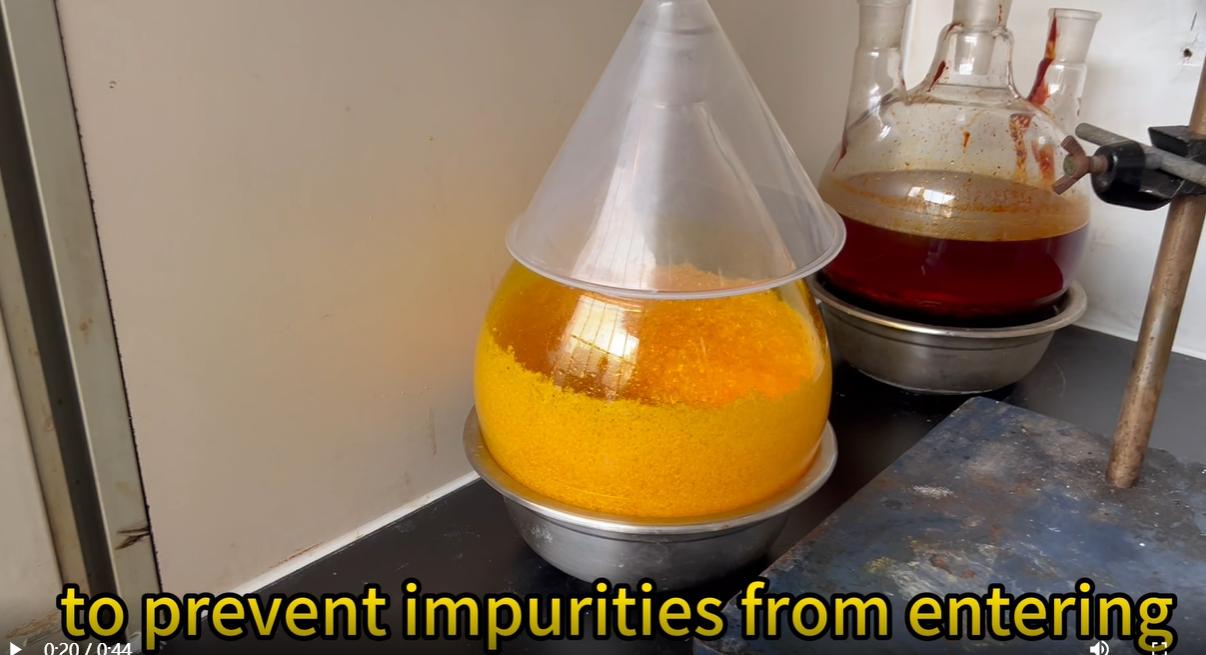

MK2866 is a commonly used compound in laboratory experiments, and it often appears in liquid form that requires purification through distillation. When the workday ends but the distillation process is still ongoing, we don’t rush to finish or simply leave it exposed. Instead, we follow a standardized “temporary storage” protocol. First, the spherical flask containing the liquid is carefully placed in a safe location, and the opening is sealed with plastic film or wrap. The main purpose of this step is to prevent dust, moisture, or other impurities in the air from entering the container and contaminating the liquid.

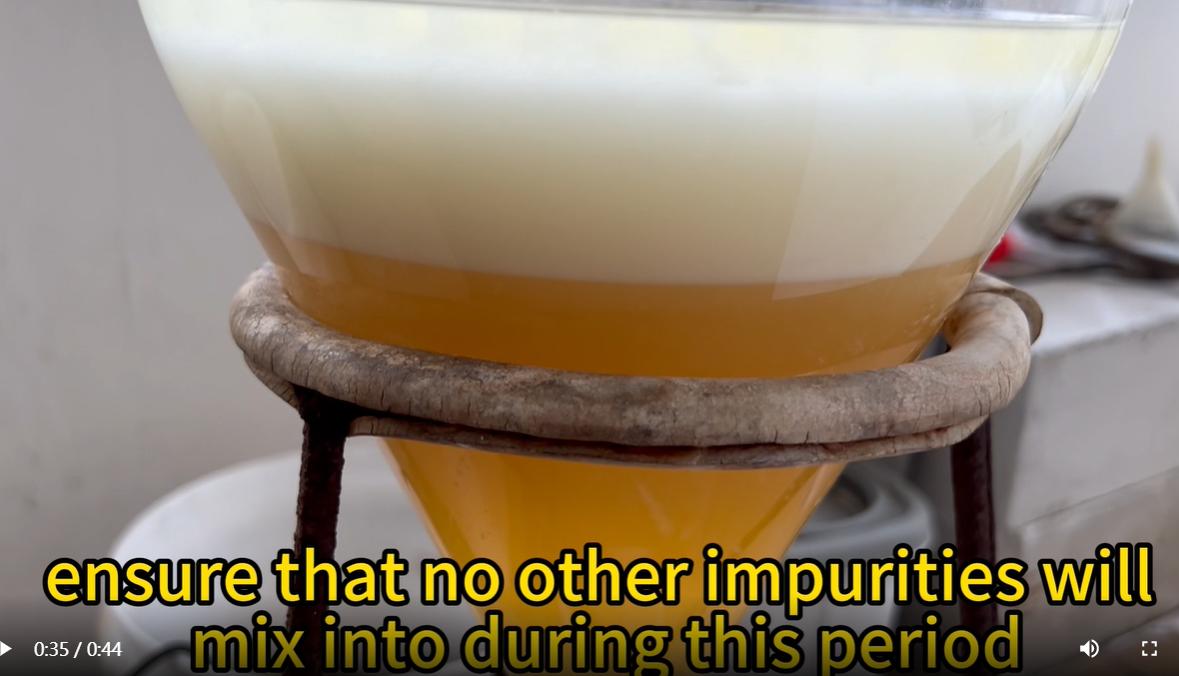

For liquids in the lab that need to stand and separate into layers, the process is very similar. Some chemical solutions naturally separate into distinct layers over several hours or longer. During this time, we seal the containers and allow the liquids to stand undisturbed, ensuring that no external contaminants interfere and that the separation process proceeds as expected.

The core principle of this handling method is: "let it settle, seal it, and protect it from contamination." We first allow the liquid to sit undisturbed in the container, giving it time for physical changes or reactions to occur, then securely seal it to prevent any external interference. This approach not only helps continue the experiment seamlessly the next day but also ensures the accuracy of results and the consistency of the final product's quality.

It’s worth noting that this method is not limited to MK2866. It applies broadly to many types of unfinished liquids in the lab—such as reaction intermediates, extraction solutions, or filtered residues. Every experiment requires patience and proper procedure, and handling unfinished processes with care is essential for maintaining scientific rigor.

In conclusion, scientifically and systematically managing unfinished liquids in experiments or production is key to maintaining continuity and upholding quality standards. What might seem like a simple act—covering a flask with plastic wrap and letting it sit—is actually rooted in a deep understanding of lab protocols and quality control. Have you ever encountered similar situations in your experiments? Feel free to share how you handled them.