Key Steps in RAD140 Production – The Application and Importance of Reaction Kettle

In the field of pharmaceutical research and synthesis—particularly in the production of selective androgen receptor modulators (SARMs) like RAD140—the reaction kettle plays a critical role. As a novel performance-enhancing compound, RAD140 is gaining increasing attention in fitness, muscle building, and anti-aging domains. Among the essential equipment involved in the synthesis of RAD140, the reaction kettle stands out as a fundamental and decisive component. Today, let’s delve into the application of reaction kettles in the production of RAD140 and their importance in the synthesis process.

The Role of the Reaction Kettle

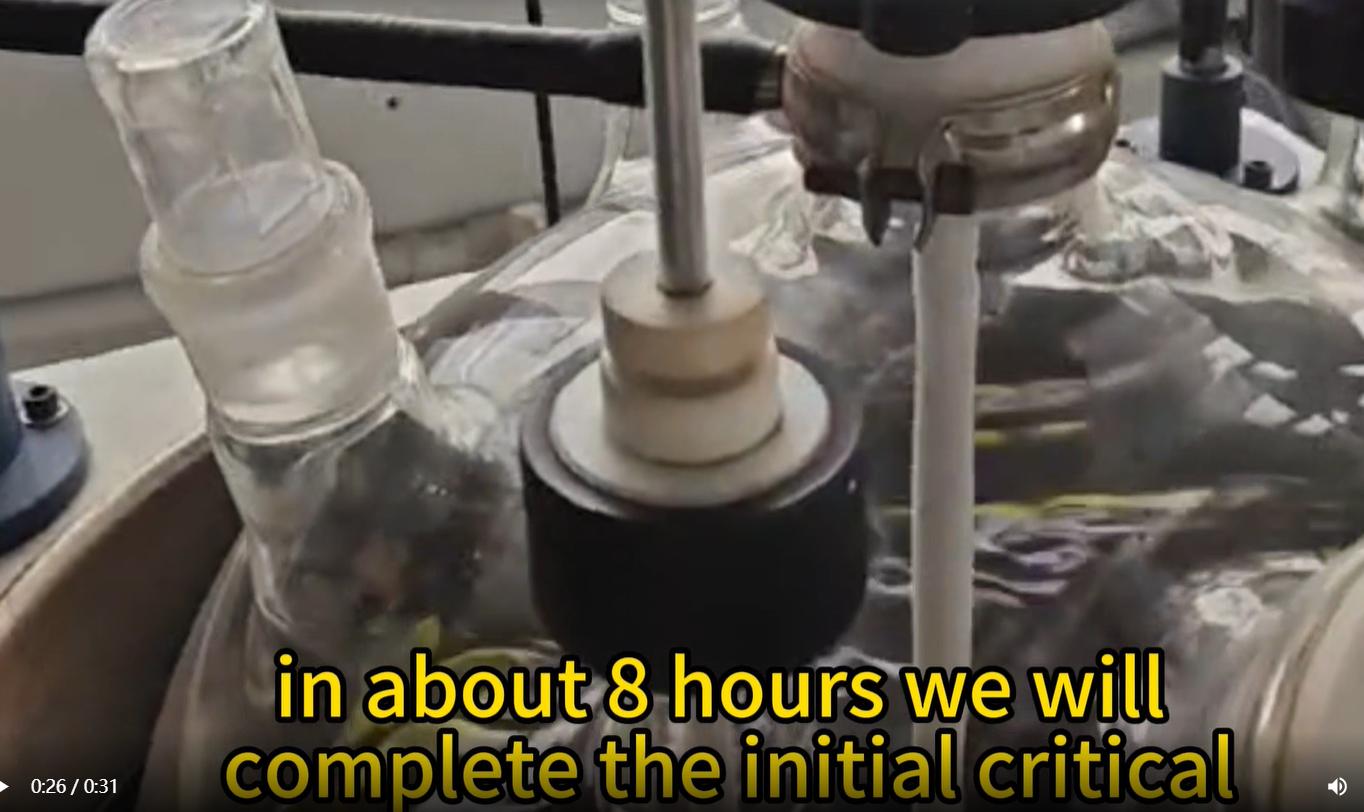

A reaction kettle is a vessel used for carrying out chemical reactions, typically under controlled temperature, pressure, and time conditions. In the production of RAD140, the reaction kettle is employed to synthesize key intermediates. The synthesis process involves multiple chemical reaction steps, each requiring precise control over reaction conditions—especially temperature, time, and solvent selection. The reaction kettle provides a stable environment to facilitate reactions under optimal conditions, ensuring the final product’s quality.

Use of High-Temperature Reaction Kettles

High-temperature reaction kettles are indispensable in the production of RAD140. Our laboratory utilizes such equipment to synthesize RAD140 intermediates. In this context, temperature control is of utmost importance. The reaction kettle operates at temperatures exceeding 80°C, providing the necessary thermal energy for efficient chemical reactions. If the temperature is too low, the reaction may proceed slowly or not at all; if too high, undesirable side reactions may occur, compromising the purity and quality of the final product.

By using high-temperature reaction kettles, we can accurately control temperature and ensure the smooth progression of intermediate synthesis. This step is crucial in the overall production process. The kettle helps accelerate reaction rates and ensure thorough completion of chemical reactions, thereby laying a solid foundation for subsequent purification and processing stages.

Reaction Time and Product Significance

Reaction time is another critical factor in the synthesis of RAD140. We typically set the reaction duration to 8 hours. During this time, all reactants undergo thorough chemical transformation within the kettle. The synthesis of RAD140 intermediates is a pivotal step that directly determines the final product's quality. Throughout the 8-hour reaction, we maintain strict control over temperature, pressure, and mixing conditions to ensure the reaction proceeds as flawlessly as possible.

After 8 hours, we obtain the precursor of RAD140, an essential raw material for synthesizing the final compound. The purity and quality of this precursor directly affect the effectiveness of the subsequent crystallization, purification, and final product formation. Therefore, the reaction kettle’s ability to provide a well-controlled reaction environment is vital to ensuring the final product’s purity, stability, and efficacy.

Challenges and Solutions in the Synthesis Process

Despite the reaction kettle's precise temperature and pressure control, challenges remain in the RAD140 synthesis process. For instance, excessive temperatures may trigger side reactions that compromise intermediate quality, while insufficient temperatures can lead to incomplete reactions. To address these issues, our laboratory continuously optimizes reaction conditions, carefully adjusting temperature and timing to ensure each step meets rigorous standards.

In addition, the design of the reaction kettle significantly impacts the synthesis process. Factors such as the kettle’s material, mixing mechanism, and sealing capabilities directly affect reaction uniformity and safety. In RAD140 production, we utilize high-performance reaction kettle equipment to guarantee both efficiency and safety during synthesis.

Conclusion

In summary, the role of the reaction kettle in RAD140 production is indispensable. From the synthesis of intermediates to the formation of the final product, the control of temperature, timing, and reaction conditions provided by the kettle is crucial. With precise process control, reaction kettles ensure that each stage of synthesis is conducted under optimal conditions, thereby guaranteeing the production of high-quality RAD140. As technology continues to advance, we believe that reaction kettle technology will continue to evolve, enhancing the synthesis processes of RAD140 and other pharmaceuticals, ultimately delivering safer and more effective products to consumers.